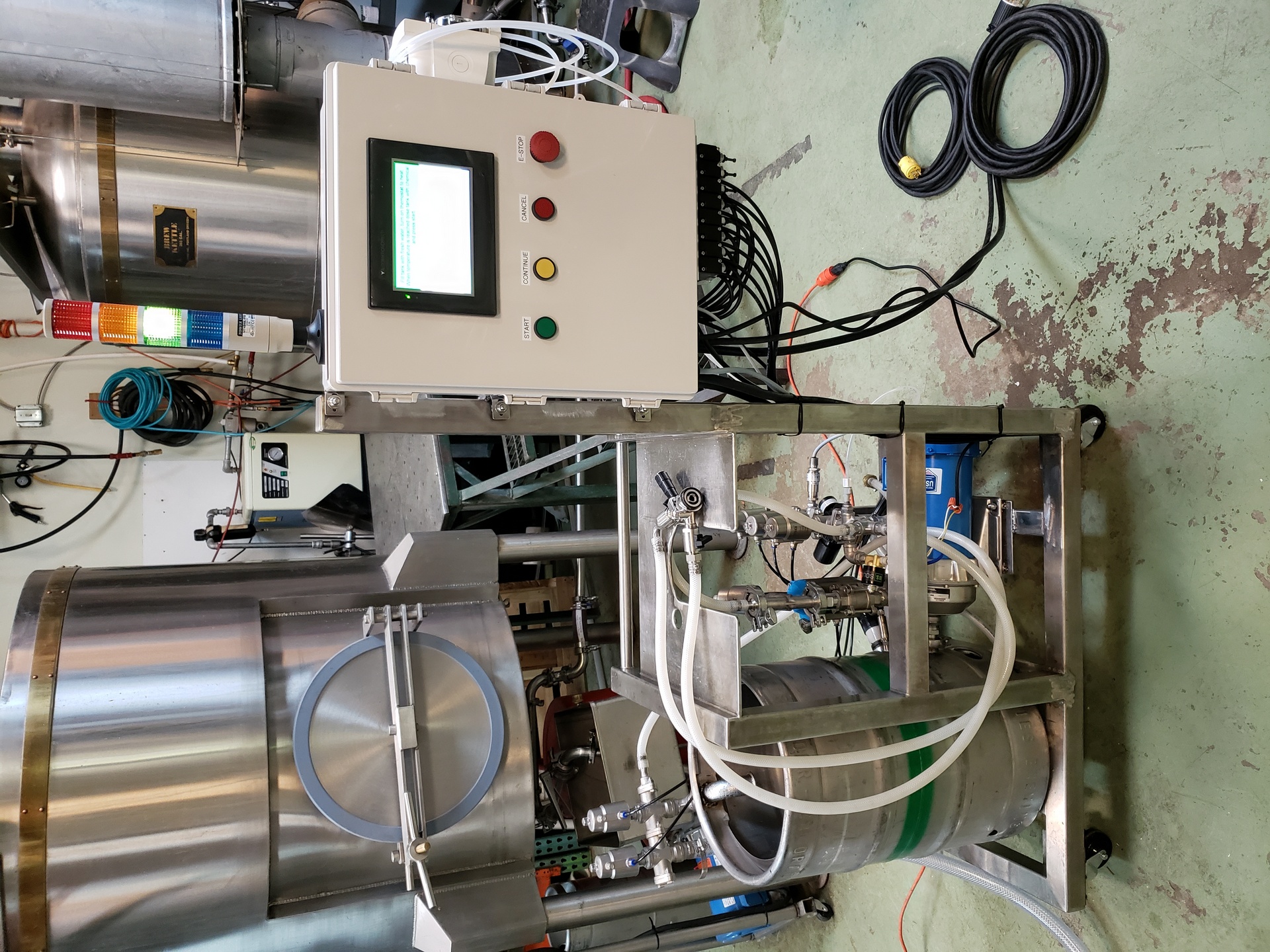

3 Head, Dual Tank, Semi-Automatic Keg Washer

This model is a 3 head recycling sanitizer washer. It is one of the most fully featured washers we make. Sensors include a thermometer for caustic temperature control, a liquid sensor for maximum cycle speed, and pressure sensor to regulate the amount of CO2 pressure in the finished clean kegs. Level switches are installed in both chemical tanks for dry fire protection.

Features

- industry standard pneumatic angle seat valves

- enclosed, water resistant control box

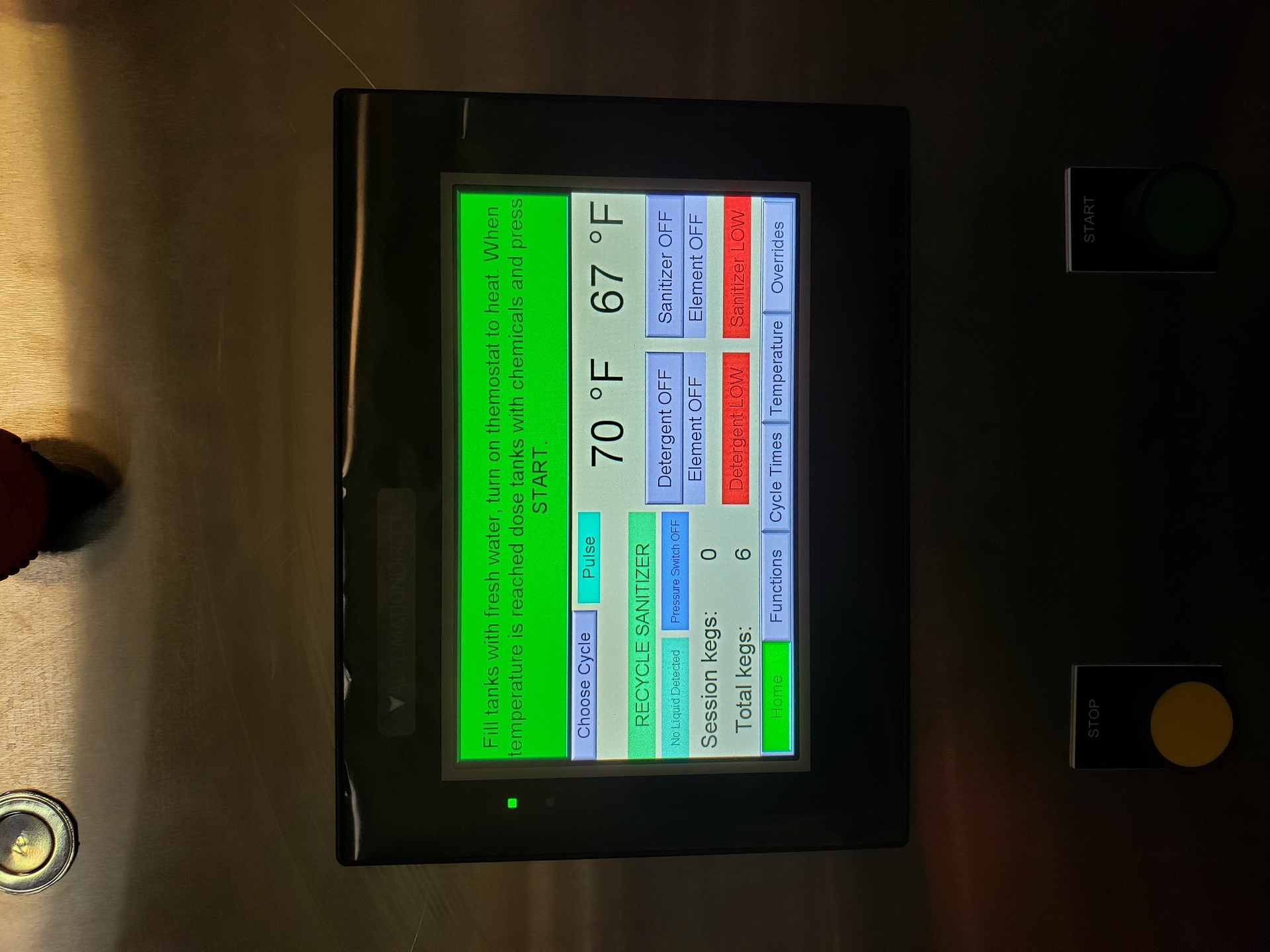

- resistive touchscreen

- extra cycles including pulse rinse or custom cycles available

- (2) 3/4 HP pumps for detergent and sanitizer

- 6000kW heating element

- temperature sensor

- caustic/detergent tank

- acid/sanitizer tank

- adjustable low flow valve for stem cleaning

- highly visible light tower indicating status

- element dry fire protection

- stainless build

- built on lockable castors for easy moving

- individual control of all devices - use this machine to heat CIP solution or draft line cleaning solution

- can customize for any electrical service

- infra-red liquid sensor

- user adjustable pressure sensor